Name:

Shanghai rubber like silicone compound mold

Classification:

Silicone compound mold pouring

Brand:

Lingying Model

Hotline:

021-69590699-127

Email:

zhengyong@jswzmx.com

Product Details

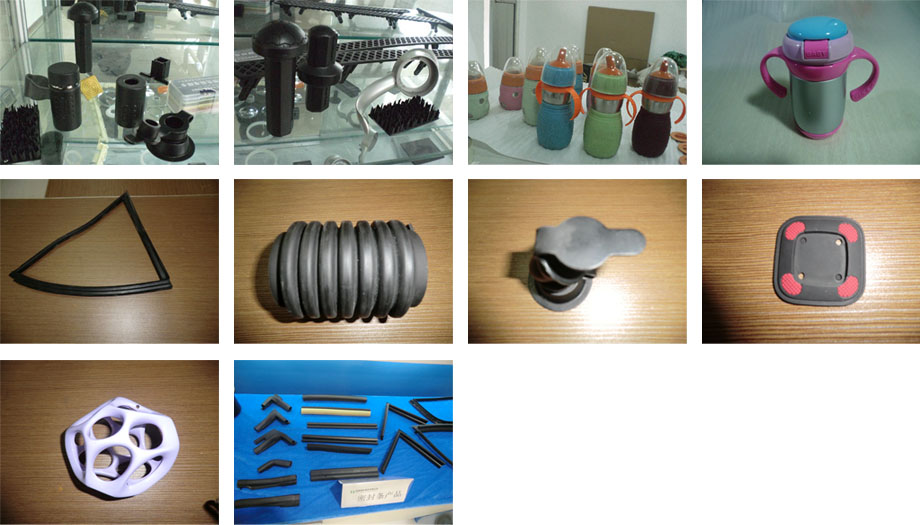

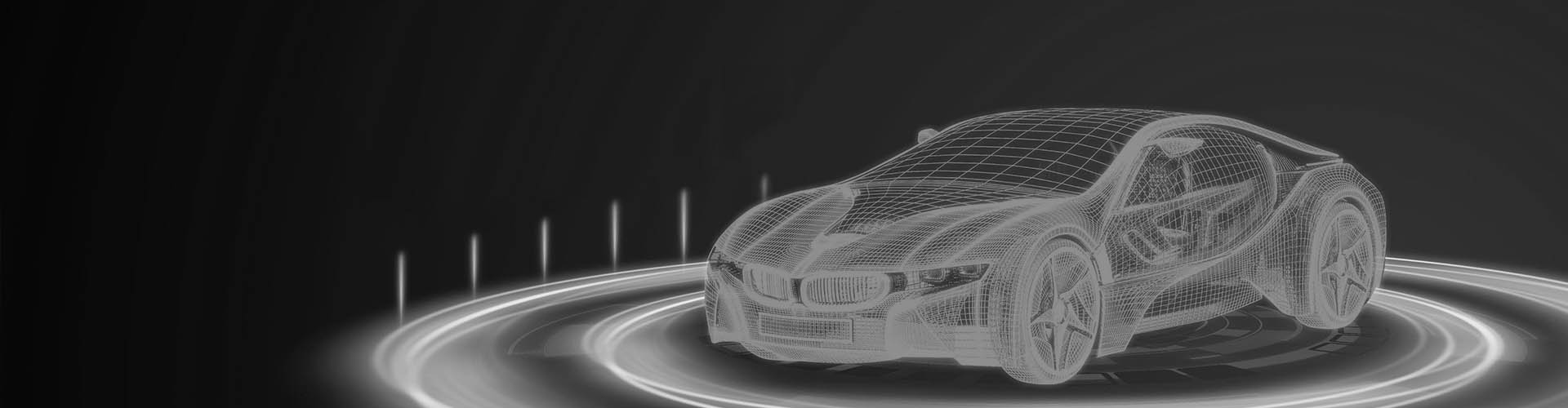

Class A silicone rubber (additive silicone rubber) for copying has excellent volume stability and accuracy. It has stable Shore hardness (two kinds of hardness are available), and it has good elasticity as well as its high tensile strength to ensure the smooth removal of the model. The reproduced model has extremely high fineness and morphological stability. The impression can be kept for a long time and can be poured repeatedly after several months, which is very important for the replica materials.

Recommended usage

1. Put the model in the standard duplicate box, do not wet the model and keep its temperature at 18 ℃ in the room temperature range— 25℃

2. Shake up the two bottles of materials, take out the materials according to the model size of about 100g or 200g, and mix them in 1:1 ratio for 30 seconds until the color is uniform. If the automatic mixer system is used for operation, shake up the materials and use them up within 3 or 4 weeks.

3. Pour the duplicate mold material on the dried mold surface in the duplicate mold box, and the operation time is about 4 minutes& ensp;

4. Keep the temperature of the duplex material in the room temperature range of 18 ℃— At 25 ℃ for about 30 minutes, take out the mold after solidification, and dry the female mold with compressed air& ensp;

5. The female mold can be poured repeatedly with standard plaster or cement, with an interval of 30 minutes for each pouring. We recommend using standard anhydrite, super anhydrite or refractory mold materials to fill the mold.