Name:

SLS nylon and nylon+GF sintering

Classification:

SLS nylon and nylon+GF sintering

Brand:

Lingying Model

Hotline:

021-69590699-127

Email:

zhengyong@jswzmx.com

Product Details

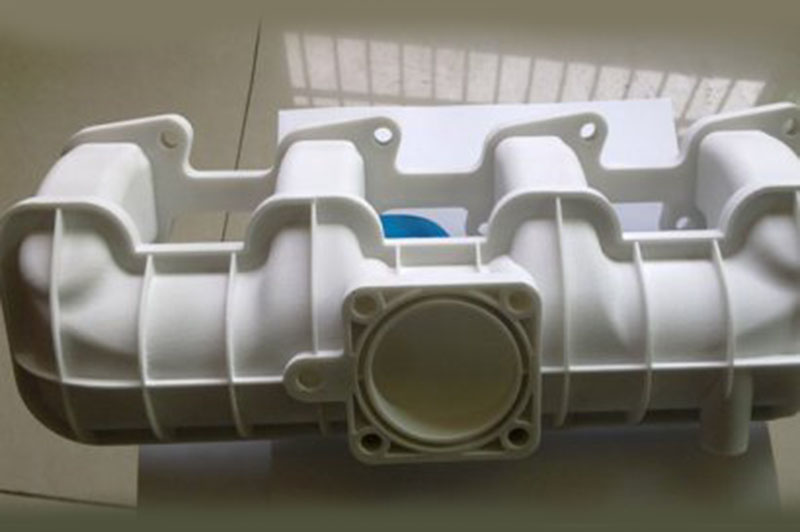

Nylon 3D printing SLS

It is also similar to SLA light curing process (resin printing), that is, all materials need to be solidified as a whole with the help of laser. The difference is that the SLS process uses an infrared laser beam, and the material changes from a photosensitive resin to a powder of plastics, wax, ceramics, metals or their composites, such as nylon powder. First, a very thin layer (sub millimeter) of raw material powder is not spread on the workbench, and then the laser beam under the control of the computer is scanned according to the two-dimensional data of different layers at a certain speed and energy density through the 3D scanner. The laser scanned powder will be sintered into a solid sheet layer of a certain thickness, and the non scanned area will remain loose powder. At present, most materials made in China are nylon 3D printing, and most of them are nylon glass fiber 3D printing.

working principle

Preheat the powder to a temperature slightly lower than its melting point, and then pave the powder under the action of the roller or scraper; Under the control of the computer, the high-intensity CO2 laser selectively sintered the section of the part according to the layered section information, and bonded with the formed part below; After one layer is completed, the next layer is sintered. After all sintering is completed, remove the excess powder, and then a sintered part can be obtained.

Comparison of advantages and disadvantages

Advantages:

Suitable for complex mechanisms or parts with special geometric shapes, nylon 3D printing can meet small batch/customized production

Good material strength, no need to add support for processing

Short processing cycle and low cost

Optimize structure and expand thinking

- Previous: SLS nylon and nylon+GF sintering

- Next: SLS nylon and nylon+GF sintering